Why Your Scraper Blade Might be Causing Tablet Weight Variation

Tablet weight consistency isn’t just a metric in quality control; it directly affects production and overall tablet yield. If finished tablets vary too much in weight, more tablets are rejected, more powdered product is wasted, and more errors happen in production.

Although a tablet press chiefly depends on large components to operate, the smaller parts can potentially cause the biggest problems. The scraper blade is one of these. If it is worn down or out of position, too much powder can be left on the die table (or not enough), which can lead to weight variation, waste, and reduced yield. Maintaining a tablet press scraper blade in good condition is a simple but important process in maintaining tablet consistency and protecting your tablet yield.

What Does the Scraper Blade Do?

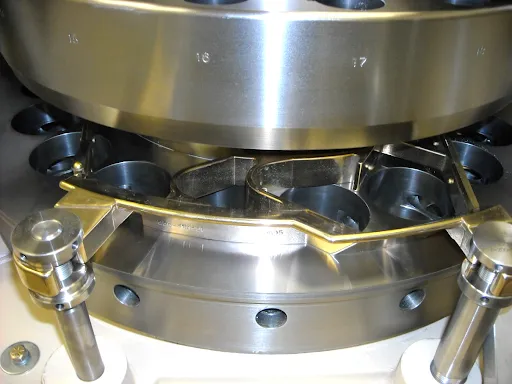

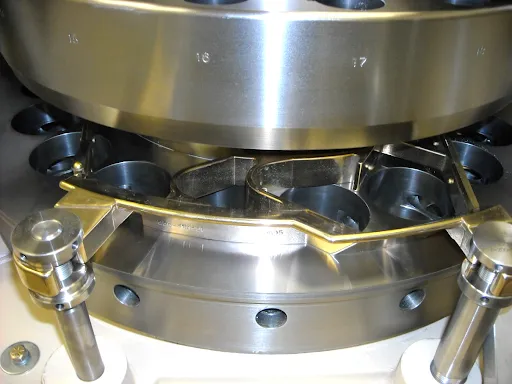

In tablet presses, the scraper blade is a small but essential part. It’s located near the feed frame on the die table. As each die passes through the fill and weight adjustment stages of compression, the scraper blade comes into play.

After the fill cam pulls down the lower punch to get material into the die and the weight cam pushes up the lower punch, excess powder that remains on top of the filled die cavity needs to be cleared away. The scraper blade removes the leftover powder off of the die table as the turret rotates so that the correct amount of material stays inside the die to be compressed into a tablet.

The scraper blade doesn’t just remove excess powder, however. It helps redirect product by recirculating the powder around the die table to the next feed frame. This keeps powder moving efficiently and helps to reduce waste.

In short, scraper blades in tablet presses ensure:

- Each die cavity holds the correct amount of powder before compression

- Excess granulation is removed cleanly

- Resuable powder is returned to the feed system without loss

How a Worn or Misaligned Scraper Blade Causes Problems

If the scraper blade isn’t working properly, it can disrupt one of the most important stages of tablet production: getting the correct amount of powder into each die.

Worn Scraper Blades

Over a period of time, scraper blades wear down due to their contact with the tablet press turret. The edge can become dull, grooved, or uneven. When that happens, it’s difficult for the blade to remove all the excess granulation after weight adjustment. Even if the weight is properly adjusted, leftover powder can indicate the pressed tablet’s weight can be off specification. Worn scraper blades also affect powder recirculation by leaving material behind that should have been directed back into the feeder.

Misaligned Scraper Blades

If a scraper blade is bent, installed unevenly, or not set at the correct height, it can result in inconsistent scraping. This means that some die cavities may be properly filled, while others are not, resulting in uneven fill across the turret.

Misalignment can come from improper scraper blade installation, worn components, or even damage to the machine. Even a slight lift on one side of the scraper blade is enough to cause tablet weight variations.

Signs of Scraper Blade Issues

Problems with the scraper blade might not be obvious at first glance. There are signs however that can give an indication of a worn or misaligned blade.

- Granulation Buildup on the Die Table: If powder is collecting on the die tablet and the fill and dosing stages, the scraper blade might be at fault. Excess granulation is being left behind, possibly due to the scraper blade being worn down, misaligned, or not making full contact with the die table surface.

- Inconsistent Tablet Weight: Variations in tablet weight can often be a result of poor scraping. Extra powder left on the die table can enter the die cavity before the compression stage, affecting the intended fill amount and resulting in tablets that are heavier than expected.

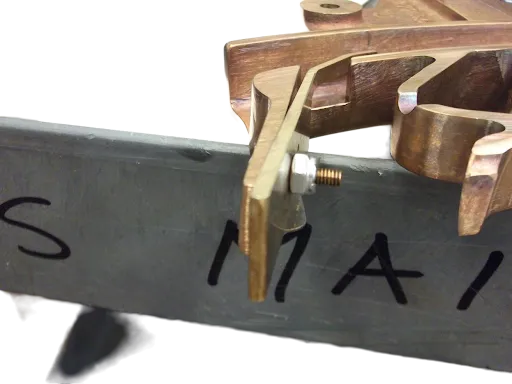

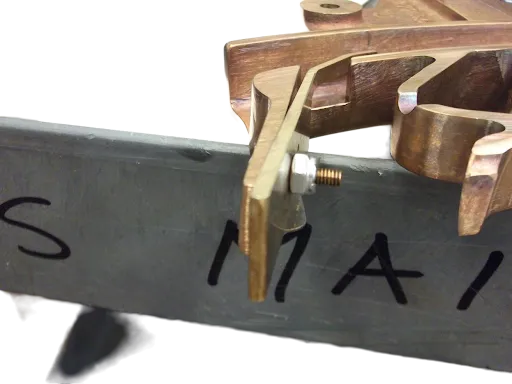

- Visible Wear, Grooves, or Lifting of the Blade: A scraper blade’s visual appearance can reveal a lot. If there are grooves, worn edges, or a section of the scraper blade lifting away from the die table, powder won’t be removed evenly.

- Loose or Broken Blade Springs: The scraper blade is spring-loaded so it stays in light contact with the die table. If a spring is broken or too loose, the blade can’t apply enough pressure. This lets powder slip underneath or leads to uneven scraping from one side of the blade to the other.

Identifying any of these problems can help prevent larger issues, such as downtime and wasted product. Regularly checking the scraper blade helps to ensure that the tablet press stays consistent in its production.

How to Fix Scraper Blade Issues

Maintaining the scraper blade is relatively easy, but requires regular attention. Because it plays a direct part in tablet weight and yield, even small issues can become big problems if left unchecked.

Inspect During Routine Maintenance

Whenever the feed frame is removed, whether during cleaning or changeovers, always inspect the scraper blade’s condition. It’s one of the easiest parts to overlook because it’s small, but it should be checked just like essential parts such as punches and cams. Any signs of wear, buildup, or uneven positioning should be corrected right away.

Replace Worn or Grooved Scraper Blades

Scraper blades are wear parts. Eventually, the edge that contacts the die table can develop grooves, flat spots, or rounded corners. These worn areas stop the blade from properly sweeping off excess granulation. It might not be visible at first, but may manifest as tablet weight variation. Replace the scraper blade if the surface is no longer smooth and straight. It’s a low-cost part compared to producing tablets not meeting specification, rework time, or lost material.

Check the Springs for Proper Pressure

The scraper blade should press lightly but consistently against the die table. Springs hold it in place, which allows the scraper blade to adjust to minor variations without digging into the die table. If a spring is damaged, missing, or too loose, the scraper blade may lift away from the table or fail to scrape evenly. During maintenance, gently press on the blade to see if the spring tension is uniform.

Verify Scraper Blade Alignment

A common issue is improper installation of the scraper blade. If it is mounted at an angle, too far from the die table, or pressed harder on one side than the other, the scraper blade won’t work correctly. Use a feeler gauge to confirm that the blade is level across the die table. Also, see that the scraper blade is always evenly secured.

“Modifying the position of scrapers can certainly affect product yields,” says Jeff Lucas, Technical Support Manager at Scheu & Kniss. “The scrapers that follow the feeder, just prior to upper punch penetration of the die, are there to ensure the product stays in the cavity where it belongs.”

Preventive Steps to Avoid Scraper Blade Problems

Preventing scraper blade issues is much easier than dealing with tablet weight problems after they start. With a few techniques, you can avoid a lot of troubleshooting and downtime in tablet production.

Add Scraper Blade Checks to Routine Maintenance

Regular checks catch wear before it becomes a problem. Make scraper blade inspection part of your maintenance checklist.

- Look for visible wear, grooves, or buildup

- Check spring tension and scraper blade movement

- Ensure scraper blade sits evenly against the die table

- Inspect more often for long runs or abrasive formulations

Inspect After Every Tooling or Feed Frame Changeover

Changes to tooling or the feed frame may possibly shift the scraper blade. Always check to see if this has happened after making adjustments.

- Confirm the scraper blade is aligned front-to-back and side-to-side

- Make sure springs are seated correctly

- Watch for gaps between scraper blade and die table

- Wipe down scraper blade and feed frame to check for loose powder

Train Operators to Identify Problems Early

Tablet press operators are in the best position to notice scraper blade issues. When trained properly, operators can act before tablet quality goes down.

- Teach how to identify buildup or overfilled dies

- Show signs of wear like grooves or lifted edges

- Have them scheck scraper blade movement during setup and cleaning

- Encourage reporting small issues before they grow

These small steps can help prevent bigger issues with tablet weight and machine performance. Checking the scraper blade should be an important part of routine maintenance.

Small parts, like the scraper blade, play an important role in tablet manufacturing. Although it’s easy to consider it minor, it can cause serious problems such as inconsistent tablet weights, lower yield, and excess product waste. This means batch failures, rework, or downtime.

Being proactive in checking the scraper blade means issues are easy to catch and fix. Making scraper blade inspections a part of the maintenance routine can help tablet quality, reduce waste, and keep production efficient.

Do you need a replacement scraper blade? Or do you want to stock up on multiple?

Scheu & Kniss offers high-quality scraper blades that are compatible with a wide range of tablet press machines, including OEM models. Contact a tablet press spare parts expert from Scheu & Kniss today to get the right fit for your tablet press.